The rear lever on the RAV 4 keeps the hub with the wheel in the specified position. If the part is damaged or the joints are worn, the car's handling is disturbed, and a knocking sound appears when driving on rough roads. The owner of the crossover can make the repair himself or turn to a specialized service center.

Contents of the article:

Diagram of the rear suspension of the RAV4

Toyota RAV4 rear levers

Upper transverse

Lower transverse

Longitudinal

Original spare parts

Spare parts analogs

Fenox

TRW

JapanParts

Masuma

Febest

ASVA

Replacing the rear arms on the Toyota RAV4 with your hands

Upper trailing arm

Lower cross arm

Trailing arm

Rear suspension diagram of RAV4

Regardless of the year of manufacture the independent lever suspension of the rear wheels is used on Toyota RAV4. Telescopic shock absorbers and cylindrical springs with non-linear stiffness are used as elastic elements.

The design includes a transverse stability stabilizer. To adjust the camber before the IV generation used a cylindrical cross-arm with variable length by means of a threaded sleeve, subsequently replaced by a bolt with an eccentric head.

Toyota RAW4 rear arms

The suspension elements are mounted on a spatial steel sub-frame attached to the body side members. The arms are fitted with rubber joints (silent blocks), which provide mobility of the elements within limited limits. The running gear scheme includes asymmetrical transverse elements, supplemented by a longitudinal arm with a support, attached to the underbody. The configuration of the parts depends on the crossover generation.

Upper transverse.

The upper arm is equipped with a pair of rubber joints and is made using hot stamping technology. The element provides the positioning of the cam with the brake mechanism and the wheel. On the I and II generation machines, the shock absorber was mounted to the cup in the body, starting from the III generation the upper fixation point of the strut is located on the subframe next to the tie rod hinge.

The upper transverse arm is stamped.

Lower transverse

The lower one is stamped from thick walled steel sheet and has a ring recess for spring installation. The arm swings vertically on hinges along with the cam and wheel.

The spring ends are lined with durable rubber gaskets to prevent noise and reduce wear rates.

Longitudinal

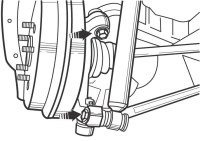

The longitudinal member is bolted rigidly to the cam. The opposite end has a pivot that provides vertical suspension travel. The sliding support is mounted in a stamped bracket bolted to the booster on the underside of the body side member.

The longitudinal arm is bolted to the cam.

Original Spare Parts

Selecting parts is carried out by using a catalog, where you must specify the VIN of the car or enter the year of manufacture, engine power and type of transmission. Original spare parts are marked with a QR-code, which reduces the risk of falsification. If the picture, scanned by a cell phone, isn't deciphered or the information about another part is displayed, it is necessary to refuse purchasing and using such products.

List of original part numbers for the 2006 RAV4 crossover:

48710-42020 (same left and right);

left cross-arm 48790-42020 (called by the owners "boomerang" because of the configuration, the part with the part number 48770-42020 on the right side)

"boomerang" mounting bolts 91672-L1265 with mating nuts 90178-12009.

There are ball pins inside the boomerang supports, which are covered with a rubber dust cover. The manufacturer puts a grease in the cavity during assembly to protect the surfaces from corrosion and abrasion. Car owners add or change the grease (e.g., for ShRB-4), which allows you to increase the life of the components.

When performing the work it is necessary to carefully remove the dust cover, and then tightly put the cover in place and secure it with the standard wire clamp.

Analogues of spare parts

Since the original parts from Toyota concern have a high price, many owners are looking for components from alternative suppliers. There are products from factories in China, Europe and Southeast Asia on the aftermarket. The common disadvantage of compatible products is unstable quality (even within the same batch), so using these units is fraught with additional costs for repeated repairs.

Fenox

The Fenox brand, claimed to be Russian-Belarusian, is supplied with Chinese components.

Fenox supplies Chinese components.

The parts are packed in boxes with the original markings (under the same part number products from different manufacturers can be supplied, which negatively affects the quality). The components are suitable for budget repair or before selling the car, but the life of the suspension will be from 5 to 15 thousand km (depending on operating conditions).

TRW

The American brand TRW Automotive supplies components to factories and the aftermarket. The quality of the products depends on the place of production (some parts from Chinese companies are packed in their containers and sold as their own products).

On the website of the manufacturer there are catalogs that allow choosing accessories according to the model of the machine and its design features.

JapanParts

The company is registered in Italy and belongs to the category of companies that pack the products of manufacturers from Southeast Asia in the original containers with their own brand. Buyers note the unstable quality of the components, which depends on the batch and supplier. The advantage is the low price and availability of parts in stock (delivery time varies from 1 to 3 days). JapanParts components are suitable for budget repair, but the life of the chassis will not exceed 1.5-2 years.

JapanParts products have a low price.

Masuma

Japanese supplier offers parts made in factories in Southeast Asia. Parts match the dimensions and material of the factory samples and withstand harsh operating conditions. Metal surfaces are coated with primer and an additional layer of impact resistant enamel, protecting the material from road reagents and water. Masuma company uses frost-resistant rubber, which does not crack when exposed to cyclic temperature changes.

Febest

The company is registered as German, but production facilities are located in China. The products are low cost and suitable for emergency repair or restoration of the chassis before selling the car. Some Febest branded parts are manufactured in large factories and have good quality, but the bulk of the parts fail after 2-3 years of use.

Febest is suitable for emergency repairs.

ASVA

Under the ASVA brand name are supplied components made by several Chinese companies. Buyers note the increased rigidity of the used rubber, which negatively affects the comfort and life. The paint coating is not durable, traces of corrosion are formed on the arms after 2-3 months of winter use (road reagents accelerate the process of rotting the metal).

Replacing the rear levers on the Toyota RAV4 with their own hands

For self-service will require a garage box with an inspection pit or an elevator. The car must be secured with chocks under the wheels or set on supports. For disassembly and assembly you will need a set of wrenches (it is recommended to have a torque arm to ensure the required tightening torque). Since the threaded joints under the underbody are covered with a layer of dirt and rust, you will need a metal brush, a rag and rust remover (such as standard WD-40).

Upper Cross Arm

To replace the upper lever, it is necessary (using the example of the 2013 model year):

Unscrew the wheel mounts and remove the disc from the hub.

Unscrew the nuts holding the ABS sensor wire, and then remove the cable from the suspension arm.

Use a rolling jack with a wooden bar or a hydraulic strut to set the suspension to its normal position.

Unscrew the 2 bolts holding the tie rod to the subframe and cam. Since the design uses self-locking fasteners, the bolt should be turned while holding the nut with a socket.

Clean the seating surfaces and holes of dirt and then install the new arm.

Insert the bolts into the holes and pretighten.

Install the suspension to its normal position (corresponding to the weight of the loaded vehicle), and then carry out the final tightening with a torque of 90 N*m (the head of the bolt should be turned, holding the nut with a wrench or head).

Reinstall ABS sensor cable, tighten nuts with 5 N*m torque.

Mount the wheel on the hub and remove the vehicle from the jacks.

Check and adjust wheel alignment in conditions of specialized service.

To replace the upper lever, remove the disc from the hub.

Lower transverse lever

To replace the cambered cross-arms in the suspension, (using the example of the 2013 model year):

Loosen the nuts, lift the car on an elevator and remove the rear wheel.

Use a pair of wrenches to unscrew the tie rod from the subframe.

Using a mounting spatula, remove the bolt from the hole and remove the tie rod from the bracket.

Place the hydraulic support under the lower mounting point of the shock absorber, and then bring the suspension to its normal position.

Use a socket to unscrew the bolt securing the shock absorber to the cam.

Pull back the strut body, unscrew the camber arm mount.

Remove the tie rod ball pin with a puller from the mounting hole.

To remove the lower arm you will need (by the example of RAV4 II generation):

Unscrew the stabilizer strut nut and the arm to cam bolt.

Remove the suspension spring from the mounting hole and move the lever down.

Remove the floating joint from the hole using a mandrel (e.g. a steel tube of suitable size). The manufacturer does not supply the original silentblocks, offering a complete cam replacement, so you will need parts from a third-party supplier to do the work.

Apply a thin coat of grease to the hinge body and insert in place, then reassemble the assembly in reverse order.

Longitudinal arm

To change a longitudinal control arm in the rear suspension, (using the 2007 model year vehicle as an example)

Remove the wheel, and then remove the handbrake cable bolts.

Place the suspension in a position corresponding to the weight of the loaded vehicle (for example, using a jack placed under the front of the brake disc).

Unscrew the arm bolts from the cam, and then remove the element from the body together with the bracket.

Install the new part in place and tighten the brackets.

Secure the handbrake cable, remove the jack, and reinstall the wheel.

When performing work related to the rear suspension on a 2008 RAB-4 crossover (and any vehicle with a lever independent design), wheel alignment may be compromised. Some owners pre-mark the eccentrics and subframes corresponding to the correct adjustment. When the work is complete, the bolt is set to its original position. To improve drivability and reduce tire wear rate, it is recommended to check the angle on the bench, as new joints and arms may adversely affect the adjustment.